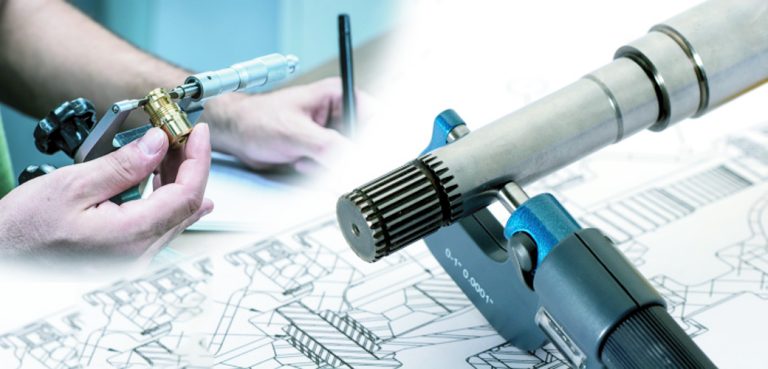

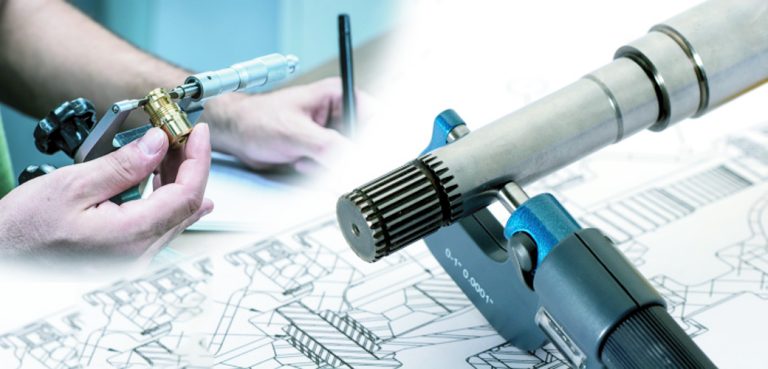

Our process

Introduce the processes from material, design and development, cnc machining, surface treatment, assembly, test and measuring to packaging.

Fabrication perfection

All Boly facilities are certified to operate under the guidance of various international standards for quality management systems based on their respective customer requirements and products.

Conformance to these standards ensures that Boly maintains the highest level of product quality and process control in their manufacturing facilities. In addition, many Boly components are certified by SGS as well as tested and approved to the US/EU Standard.

Focus on lean production

All our facilities operate under lean manufacturing and continuous improvement principles to increase efficiencies and reduce costs while maintaining the highest level of quality. Lean methods include improving workplace organization, reducing set-up times, streamlining process flows, continuous employee training, and more. Through lean, we’ve streamlined processes to ensure our clients receive the best prices, products, and services in the industry.

We provide a full line of CNC and Swiss turning and secondary operation capacity for finishing complex workpieces. An extensive complement of imported Japanese Swiss turning machines employing the latest technologies provides the precision advantage to meet close tolerances, tight concentricity, fine finish, and complex features.

We offer assembly to complement your particular needs, often providing customers with a complete subassembly of several parts that we have also manufactured. We have seamless partnerships with an outsourcing companies, allowing us to utilize their capabilities in conjunction with our own.

- Solutions for your manufacturing business

- Production of precise tools and machines

- Quick turnaround from prototypes to volume production

- Designing, produce and testing with highest quality

- A full range of finishing requirements