Sensor Applications

We provide superior sensor housing and mechanical components to the sensor industry and create value-added solutions for customers to match the reliability and performance of sensor products.

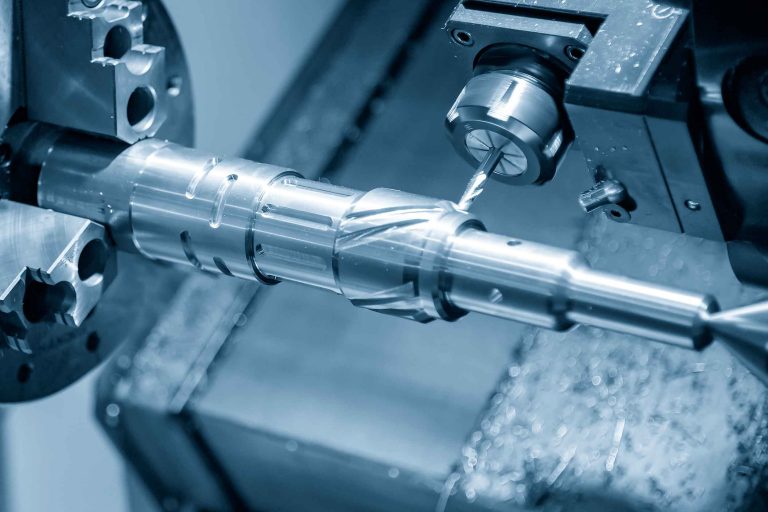

Machined parts for Sensor

Boly serves industrial customers sensing element parts used in fluid, pressure, motion, position and temperature control metal parts. These sensor components are manufactured by CNC machining and surface treatment, in materials of Stainless Steel, Nickel alloy, Brass, Aluminum, any other material composition based on custom specifications and requirements. With in-depth expertise in fabricating high precision custom sensor components, including metal parts for Gages, Transmitters, Switches, Data Loggers, and Monitors which are rely on Pressure and Mechanical technology.

We supply precision components to sensor manufacturers, serving small customers and large OEMs in the global market. Sensor technologies provide measuring and thus accurate controls in machinery. Boly provides a series of comprehensive and effective metal components solutions to meet the different needs of sensor manufacturers, so as to improve production efficiency and reduce costs effectively.

High-Quality Custom Sensor Parts

We supply the Sensor Industry with superior mechanical components and assemblies to match the reliability and performance of your Sensor products. We create value-added solutions for our Sensor Industry customers through collaborative relationships, engineering expertise, and innovation. Here is some key applications example:

Components for applications in the Sensor field:

- Bodies

- Terminals

- Diaphragms

- Port housings

- Headers adaptors

- Overmold rings

- Hex ports

- Sensor fittings

- Pressure ports

- Process fittings

- Transducer housings

- Process tubes

Once a product design is finalized, you can count on Boly 50+ years of machining experience to consistently produce the highest quality sensor components.

Typical precision machining Sensor Components

Machining capabilities for Sensor industry components

Precision machining methods at Boly offer a wealth of advantages for Sensor industry customers who desire parts that have high requirements for close tolerance and surface finish. We have a full range of precision machining process capabilities, including CNC turning, vertical/horizontal milling, grinding, and many secondary operations. A standard and high-quality range of sensor components withstand all types of chemical and acid sub-stances as well as extreme harsh environments. We are available with different types of coating include Passivation, Chrome, Nickle, Zinc, Tin, Copper, and more.

General Range of our sensor components are widely used in Chemical, Automotive, Aerospace, Medical, Electrical and many other Industries. When a customer requires high quality components and competitive prices, our precision machining methods offer impeccable results.

- Concept-to-delivery metals and alloy machining

- Exceptionally precise CNC Swiss machining

- CNC turning and milling up to 5-axis machine centers

- Design for manufacturing Process development

- Quick turnaround development

- In-house tool design and fabrication

- Multi-level assembly and finishing

- Laser Engraving for unique identification

- Advanced inspection technology

- Customized inventory management

- PPAP compliant for all your capability study needs

- Fully compatible with Sensor industry expectations

Our great support for Sensor components

Automated CNC Machining

Leverage high-speed 3-axis and 5-axis machining processes as well as turning with live tooling for increasingly complex metal and plastic components.

Tools and Fixtures

Get durable, production-grade tools, fixtures, and other aids within days so development and workflow remain forward moving.

Quality Certifications and Traceability

Take advantage of our ISO9001 certified machining for high-requirement parts. Material lot traceability is also available on projects that qualify.

Materials

Choose from machined metals like stainless steel, nickel steel alloys like Inconel and Hastelloy, aluminium and brass.

More on our CapabilitiesReliable Manufacturing Service

Boly offers Sensor component manufacturing with the latest equipment. We perform prototyping services, production manufacturing, and secondary processes in-house.

Material selectionWhat Specialty Materials Work Best for Sensor Components?

Nickel and High Temperature Alloys

Nickel steel alloys are extremely popular for sensor housings and fittings. It is designed for critical applications where extreme conditions are required. This demand is due to its increased hardness, tensile strength, and elastic limit, all without reduced ductility. It also maintains strength at elevated temperatures as high as 1,050˚C to 1,200˚C. The nickel-based super alloys Inconel and Hastelloy are also used extensively.

Below are some of the grades in stock:

Nickel-Chromium Alloys – Inconel®

Inconel 600

Inconel 617

Inconel 625

Inconel 718

Nickel-Molybdenum-Chromium Alloys – Hastelloy®

Hastelloy C276

Stainless Steel and Specialty Steel

Stainless steel alloys have found increasing usage in Gages, Transmitters and Switches that require great strength but can handle the increased weight. The high corrosion and temperature resistance found in stainless steel make it suitable for a range of fittings used on heavy duty pressure transducer and vacuum switch.

Below are some of the grades in stock:

AISI 303

AISI 304

AISI 316

AISI 630

AISI 17-4PH

Aluminum Alloys

There is a great deal of aluminum alloys for Sensor and UHV applications. Most aluminum alloys offer high weight to strength rations, corrosion resistance, formability, and favorable pricing.

Below are some of the grades in stock:

Aluminum 2011

Aluminum 4032

Aluminum 6061

Aluminum 6063

Aluminum 7075-T7651

Copper Alloys

With copper’s outstanding conductivity, it is the metal of choice for high over-voltage situations and ensures that the device is compliant with industry standards. It is widely used on environmental solutions for indoor applications such as building automation and HVAC systems in residential and office buildings. It is widely used for temperature switches and thermostats.

Below are some of the grades in stock:

Copper C3600

Copper C3602

Copper C3604

Copper C4926 (Lead Free)

Congratulations to Mr. Vincent Cho

Find out more

Mask Sterilization System 2

Find out more

About Us

Find out more