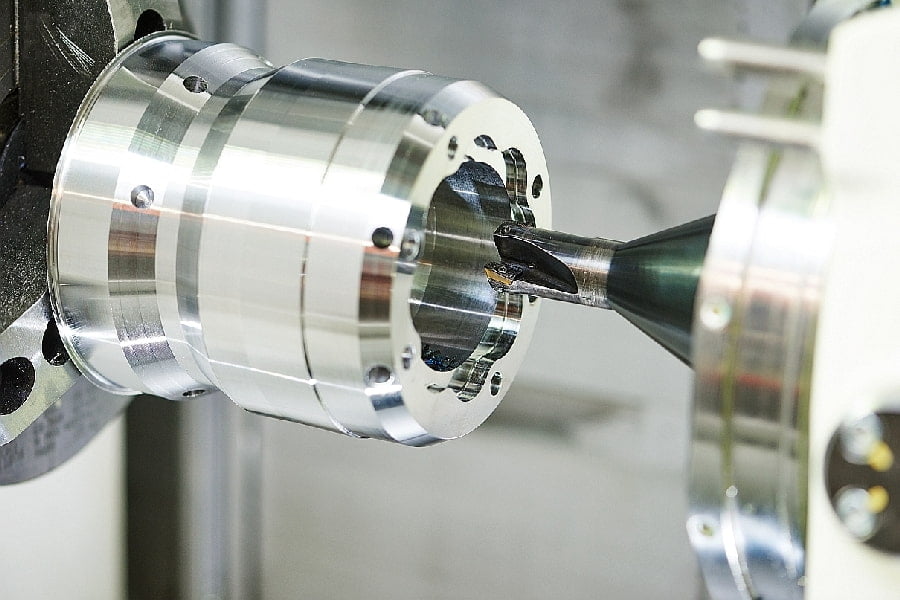

Aluminum Turned Parts

Specialized in custom-made quality Aluminum turning parts and machined parts. Precision machining components according to customers' specifications & industry standards.

Machined to specificationManufacture and supply of aluminum parts

Boly manufactures and supplies a variety of custom CNC aluminum machined parts, offering aluminum machining services. We have advanced CNC turn & mill machines and surface treatment technology to provide one-stop machining solutions. We complete the required functional dimensions and surface treatment of the parts according to the customer’s drawing specifications. Each aluminum part perfectly conforms to the customer’s product application requirements, including automotive precision parts, precision motor parts, medical instrument parts, power tool parts, machine parts, high-end electronic and home appliance parts, etc. We have demonstrated excellent quality and efficient performance in our applications.

- Commonly use 2000, 4000, 6000, 7000 series aluminum

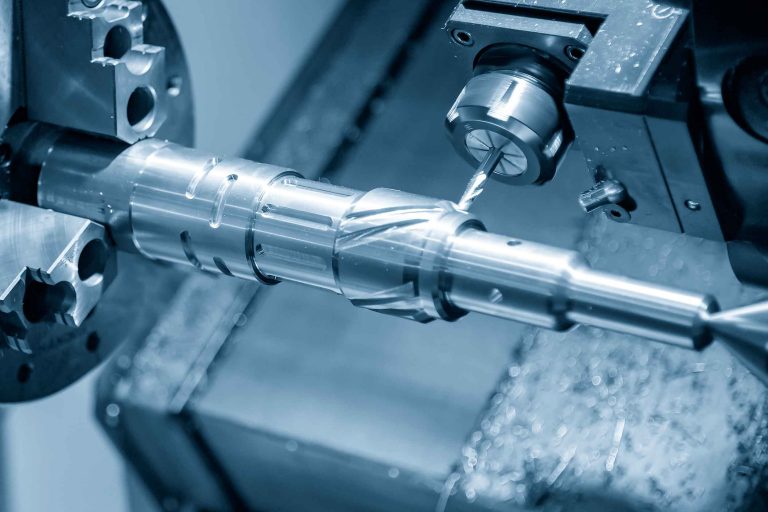

- Swiss screw machining, CNC machining and milling

- Lightweight, high strength, corrosion resistant, heat dissipation, non-magnetic

- Dyed anodizing and hardcoat anodizing available

Commonly Machined Aluminum Parts:

Aluminum is a popular choice for many products and components:

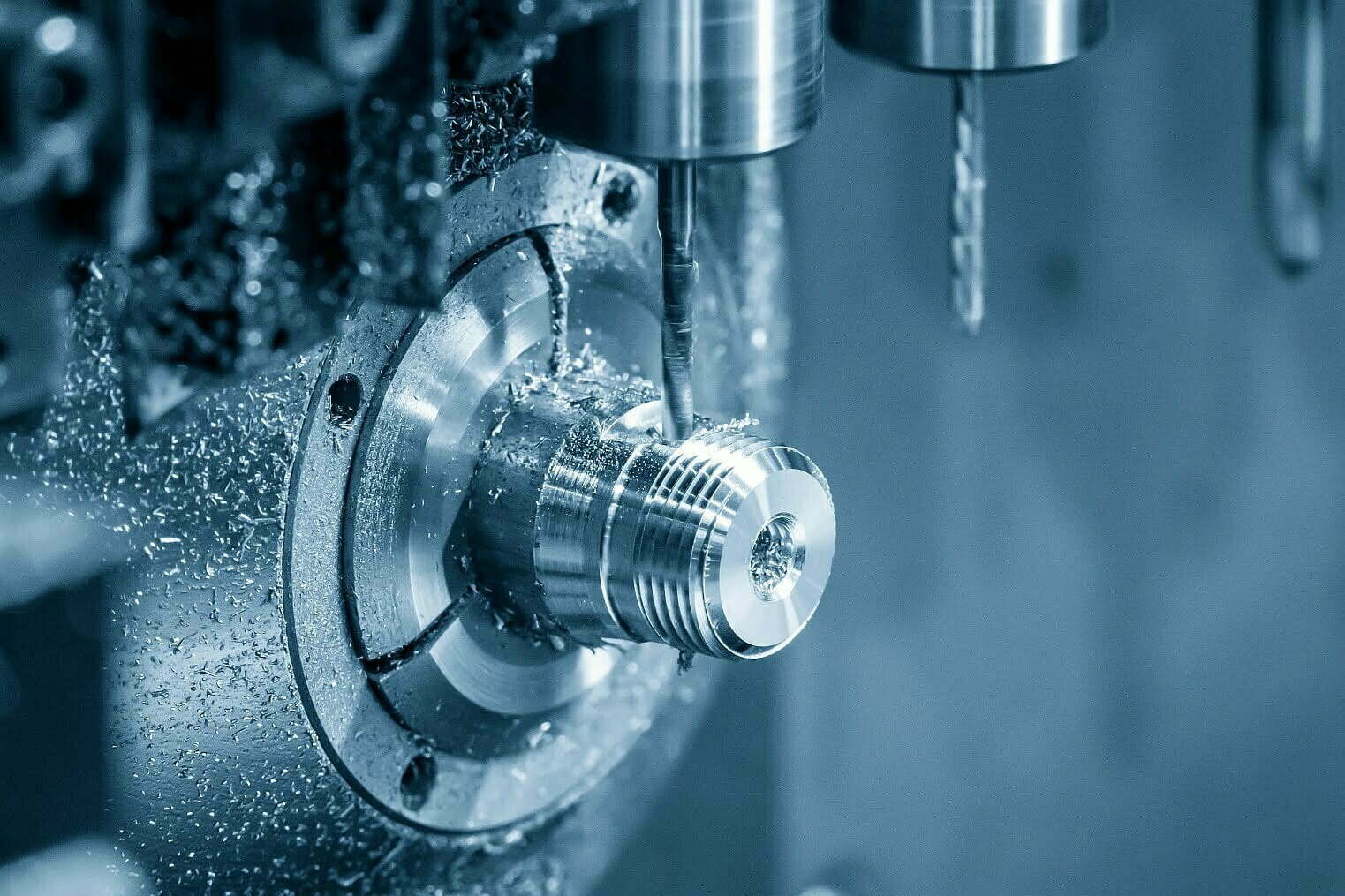

Advantages of using Aluminum

In addition to its excellent machinability, aluminum demonstrates many characteristics that make it suitable for use in machining operations, such as:

- Excellent corrosion and chemical resistance

- High strength-to-weight ratio

- Good heat and electrical conductivity

- Easily machined

- Reflects heat and light

Machined components manufactured from a variety of aluminum grades

Aluminum 2011

High mechanical strength alloy, weldability, strength, and anodizing response are all rated as average at best. Typically used in the manufacture of machine parts, screw machine products, tube fittings, pipe stems, hoses and atomizer parts.

Aluminum 4032

Offers superior service in both low and high-temperature service. Typically used in the manufacture of electric vehicle battery and motorsport applications include battery terminals, racing pistons, engines components and chassis components.

Aluminum 6061

Good mechanical properties and weldability, making it one of the most common alloys for general use. Typically used in the manufacturing of aircraft, electric vehicles parts and bicycle components.

Aluminum 7075

Good fatigue strength but is not weldable and has limited resistance to corrosion. It often used in transport applications including marine, automotive and aviation. Typically used in the manufacturing of aircraft fitting, gears and shaft, regulating valve parts.

Learn more aboutMaterial types

We manufacture a range of turned and machined parts for a wide range of applications.

Sensor Applications

Find out more

Centerless Grinding

Find out moreCongratulations to Mr. Vincent Cho

Find out more

Mask Sterilization System 2

Find out moreWhat can we help you?Any kind of aluminum components can be developed and supplied exactly as per your specifications.

Join us on a project

Join us on a project