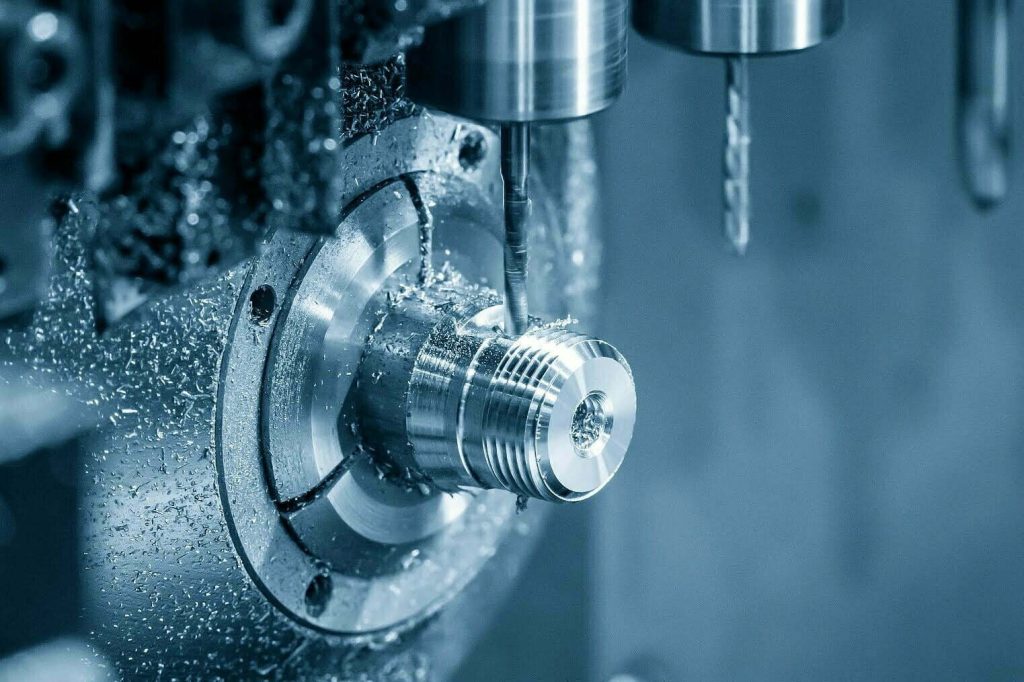

Swiss Turning

A superb method for creating precision parts. It has the capability to machine longer, slender, and more complex parts with incredible accuracy, efficiency, and throughput.

Custom-made unique component

Swiss turning is designed for miniature parts and excels in producing long slender parts. This technology allows us to perform milling, turning, threading, cross-drilling, engraving, and other machining techniques using a single machine. All-in-one machining operations like this allow us to eliminate costly secondary processes, saving time and money while ensuring the part is produced to the exact specifications.

- For 1000 to 1 mill pieces production runs

- Components machined up to dia. 20mm

- Parts require turned and milled features

- Machined with metal and plastic

- Straightness / concentricity tolerances

- High quality finishes and tight tolerances

- Delivers repeatable quality

KnowledgeAdvantage of Swiss Turning process

Compared to other machining and manufacturing processes, Swiss turning offers a number of benefits.

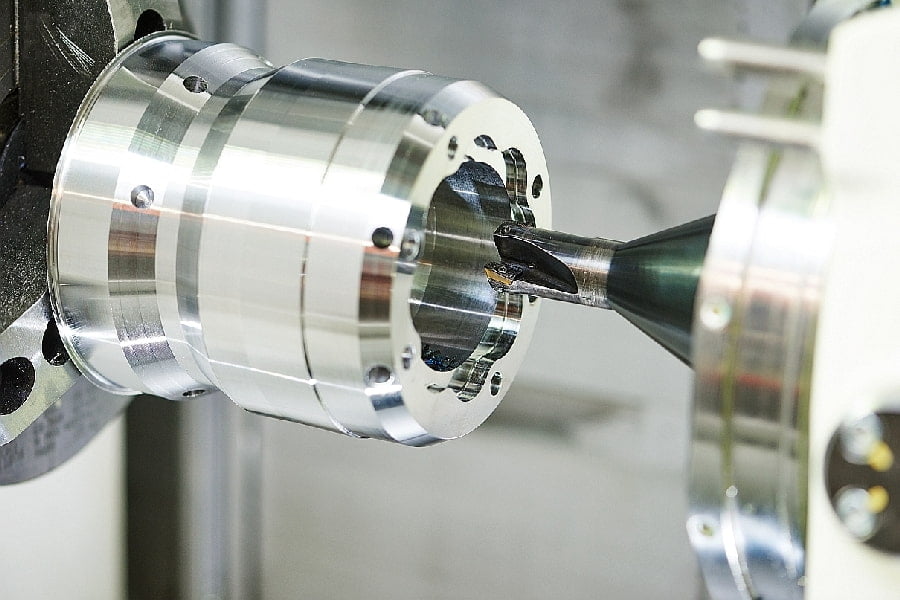

Extremely tight tolerances

Swiss machines firmly support the workpiece right next to the point of operation throughout the machining process. Because the piece is supported so close to the tooling operation, the part remains steady, virtually unaffected by the force of the tools. This ensures precision within extremely tight tolerances—even when machining very small parts.

More Complex Parts

Because of how well the bar stock is supported throughout the machining process, Swiss machines can also produce more intricate parts with thinner walls, more delicate features, and deeper cuts that would not be possible on other machines.

Fast Pace

A Swiss center performs multiple operations in a single setup, which drastically reduces cycle times and increases production volume. Also, since Swiss centers can operate lights-out, we are able to produce components near-continuously, further reducing lead time.

Ready-to-Ship Parts

Swiss machines produce such a fine and precise result that these machines can reduce or eliminate the need for secondary operations, often resulting in parts that are ready to ship right out of the machine.

About ourSwiss Turning Capabilities

- (1) CITIZEN CNC Sliding HEADSTOCK TYPE AUTOMATIC CNC LATHE

Multi Spindle Swiss. Max. Machining Dia. ∅ 32mm (1¼″). Max Spindle Speed: 8,000 RPM . X,Y,Z,B 7 axes of motion, includes 20 tools as standard including 5 live spindles, back spindle enables front/back simultaneous machining. - (5) CITIZEN CNC SWISS-TYPE TURNING CENTER

Multi Spindle Swiss. Max. Machining Dia. ∅ 20mm (.79″). Max Spindle Speed: 10,000 RPM . 8 axes of motion with 3 cross-machining and cross-milling spindle, with back spindle enables front/back simultaneous machining. - (6) CITIZEN CNC SWISS-TYPE TURNING LATHE

Single Spindle Swiss. Max. Machining Dia. ∅ 16mm (0.63”). Max Spindle Speed: 10,000 RPM . Twin turret, all crossworks: cross-drilling, cross-milling, cross-slotting. - (3) CITIZEN CNC SWISS-TYPE TURNING LATHE

Single Spindle Swiss. Max. Machining Dia. ∅ 12mm (0.5”). Max Spindle Speed: 10,000 RPM. Twin turret, all crossworks: cross-drilling, cross-milling, cross-slotting.

We stock a range of alloy & plastics material that are suitable for various part applications and industries.

- Metals (e.g., stainless steel, carbon steel, aluminum, brass).

- Exotics Alloys (e.g., Hastelloy and Inconel).

- Plastics (e.g., PEEK, Delrin and Acetal)

- ISO 9001:2015 Compliant

- RoHS and REACH Compliant

- Conflict Free Minerals

- Prototype 2-3 weeks (typical)

- Production is 4-6 weeks (typical)

- Quoted on job by job basis

- Rush Services Available

- We take customer trust seriously, employing proven quality management principles to enhance customer satisfaction and continually improve our performance and capabilities.

- We have decades of experience meeting the stringent regulations and PPAP compliant for the automotive, aerospace and medical device industries, which serve as benchmarks for all of the products we manufacture.

More from BolyRelated Precision Machining Services

We manufacture and supply customized products and provide surface treatment services according to customers’ specifications and industry standards. We are an efficient and cost-effective one-stop solution provider with the scale and capability to deliver integrated services.

Congratulations to Mr. Vincent Cho

Congratulations to Mr. Vincent Cho for the conferment of Fellowship by the Professional Validation Council of Hong Kong Industries (PVCHK) in recognition of his outstanding achievements in his professional field....

Mask Sterilization System 2

Congratulations to Mr. Vincent Cho for the conferment of Fellowship by the Professional Validation Council of Hong Kong Industries (PVCHK) in recognition of his outstanding achievements in his professional field....

Professional Validation Council of Hong Kong Industries

Congratulations to Mr. Vincent Cho for the conferment of Fellowship by the Professional Validation Council of Hong Kong Industries (PVCHK) in recognition of his outstanding achievements in his professional field....